Aluminum is one of the lightest and most sustainable building materials available. Weighing less than glass or steel, it is both strong and flexible. Aluminum is malleable and often used in projects where aesthetic curves are required. For example, The Wave – a seaside apartment building in Almere, Holland – used aluminum to create an undulating facade worthy of the structure’s name.

Aluminum is also an excellent material to work with when quality of finish is of utmost importance. Whether resistance to harsh weather is a must, or specific colours are needed for design and branding – a properly finished aluminum exterior will undoubtedly stand the test of time. Even better, should the choice to eventually replace it be made, aluminum is highly recyclable.

So, what’s the best finishing method for aluminum building components? Read on to find out!

Anodize

Anodizing is an electrolytic passivation process that helps increase the thickness of a metal’s natural oxide layer. And anodized metal component has increased resistance to corrosion and wear, as well as provides a better adhesive surface for paint primers and glue. Anodizing can also be used to create aesthetic effects such as a distortion to the material’s reflected light.

Image Credit: Alumi-Span

While all of this sounds pretty cool, it’s important to remember that anodizing is only one step in the finishing process. For example, in the most common aluminum anodizing process, sulphuric acid is used to create a porous surface that will readily accept a dye. Next, the dye itself must be applied, and then a sealant. Furthermore, while the colours available are nearly endless, the final shade’s outcome is impacted by the base alloy.

Paint

Paint is certainly a well-known and frequently used finishing method, but that doesn’t mean that it’s the best. While it’s availability and affordability make it a front-runner for finishing projects, there are a few important factors to consider before painting an aluminum component.

Image Credit: Pexels

One of the main reasons paint alternatives such as powder coating exist is because of the environmental hazards of liquid paint. Liquid paint carries harsh chemicals, is flammable, carcinogenic and is known to cause damage to the ozone layer. Paint is also one of the more wasteful finishing methods due to evaporation and the fact that overspray cannot be collected and reused.

Powder Coating

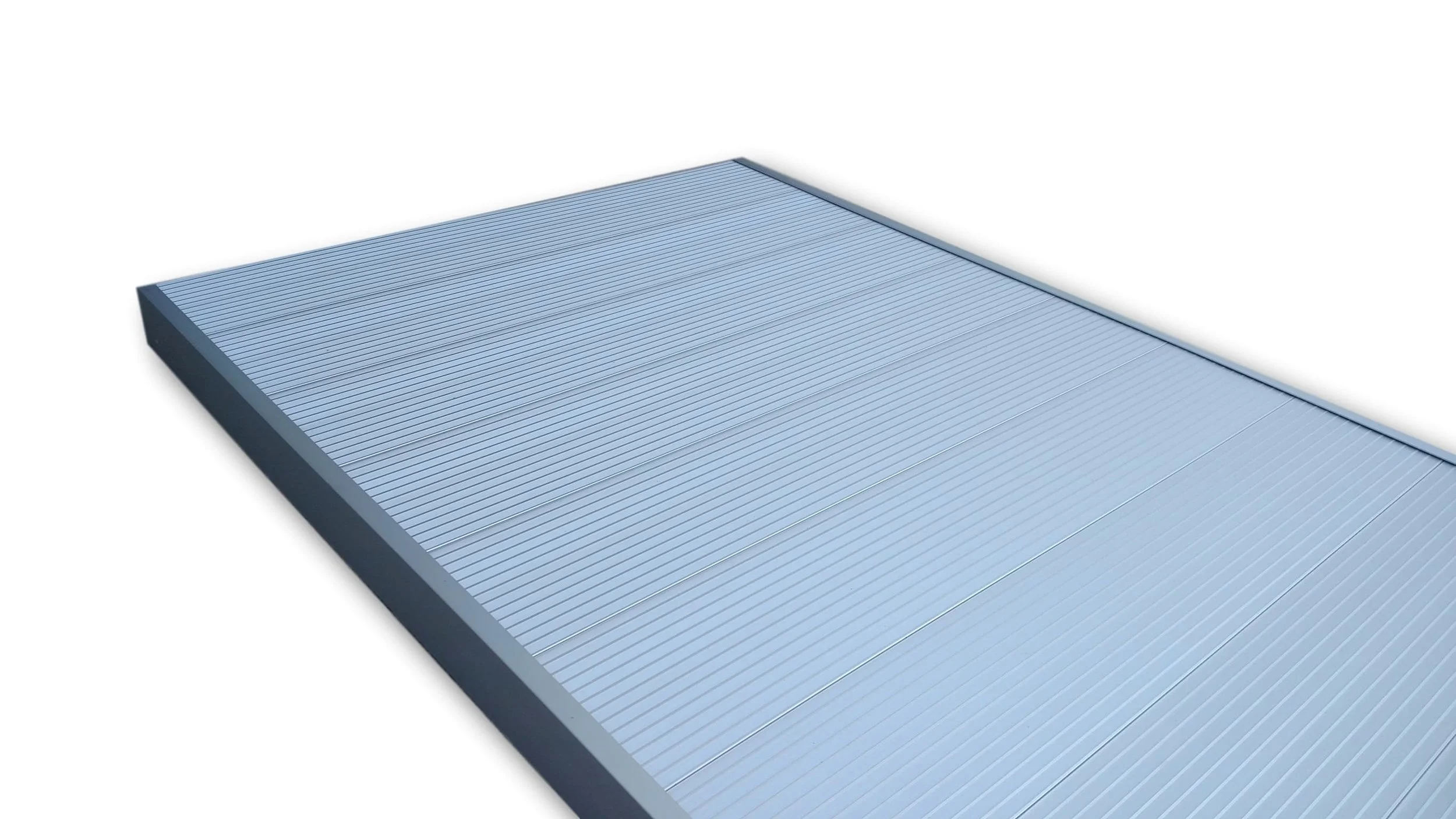

The powder coating process involves applying coloured powder to a material – aluminum, for example – by way of electrostatically charging the powder and spraying it onto the product. One of the many benefits of this process is that any overspray can be collected and reused. Also, because powder coating doesn’t contain any solvents, it is far less hazardous to both the plant and the individuals working with it.

Image Credit: Pexels

Powder coating may be newer than liquid paint, but it’s still been around long enough to prove that it is an excellent finishing method that provides a combination of aesthetics, durability and sustainability. Examples of powder coated aluminum products include siding, roofing, windows, decks, railings and more.

The Finished Product

While each of the above finishing methods has its positives, powder coating is the only choice that offers all the desired outcomes in one streamlined process. Thanks to Cadillac Coatings’ patented Paintline, each step of the powder coating process – from preparation to curing – occurs in a production line that operates at up to 15 feet per minute.

Want to learn more about our powder coating process and aluminum? Contact us today!